Product

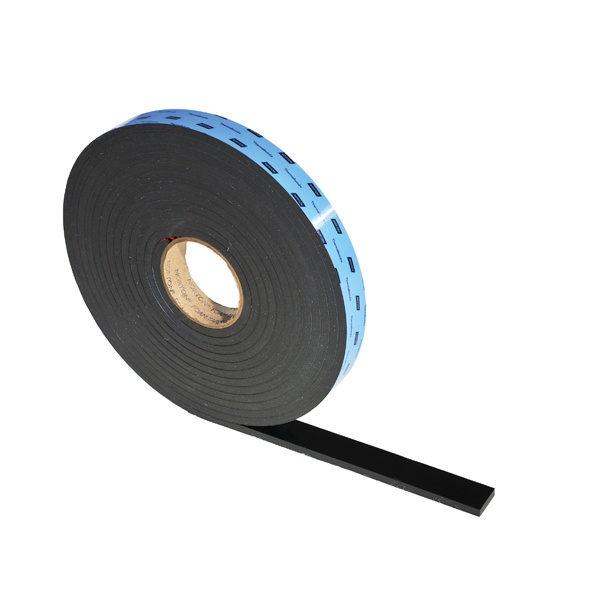

Carrier made of high density open-cell polyurethane foam with an acrylic adhesive layer on both sides.

The Thermalbond® V2100 distinguishes itself by a polyethylene liner that is easily removable without tearing. The double-sided acrylic adhesive layer is pressure-sensitive and adheres to both metal and glass, while the carrier ensures the necessary distance.

Application examples

– exceptional spacer for 2 or 4-sided glued glazing systems

– conventional spacer inside the glass

– thermal break in glazing

– vibration damper

Colour

Anthracite with blue polyethylene liner

Thicknesses mm, widths mm and roll lengths

3,20 mm: from 6 tot 1.350 mm 15,25 m

4,80 mm: from 6 tot 1.350 mm 15,25 m

6,40 mm: from 6 tot 1.350 mm 15,25 m

8,00 mm: from 8 tot 1.350 mm 7,60 m

9,50 mm: from 9 tot 1.350 mm 7,60 m

12,50 mm: from 12 tot 1.350 mm 6,10 m

Packaging

On a roll

In boxes, separated by a silicone paper

Properties/advantages

– the open-cell structure allows air and humidity to pass through to the silicone, making adhesion faster and optimal

– the high density polyurethane carrier is chemically compatible with all silicones tested*

– the very limited thermal conductivity of the carrier limits the transfer of heat and avoids condensation on glass, doors and steel

– excellent resistance to UV radiation, mildew and oxidation

– suitable for punching parts